Metal Casket Assembly

Below are the primary processes for assembling and manufacturing a metal casket. The casket goes through four main stages:

metal fabrication, application of paint, installation of the bed & hardware, and interior installation.

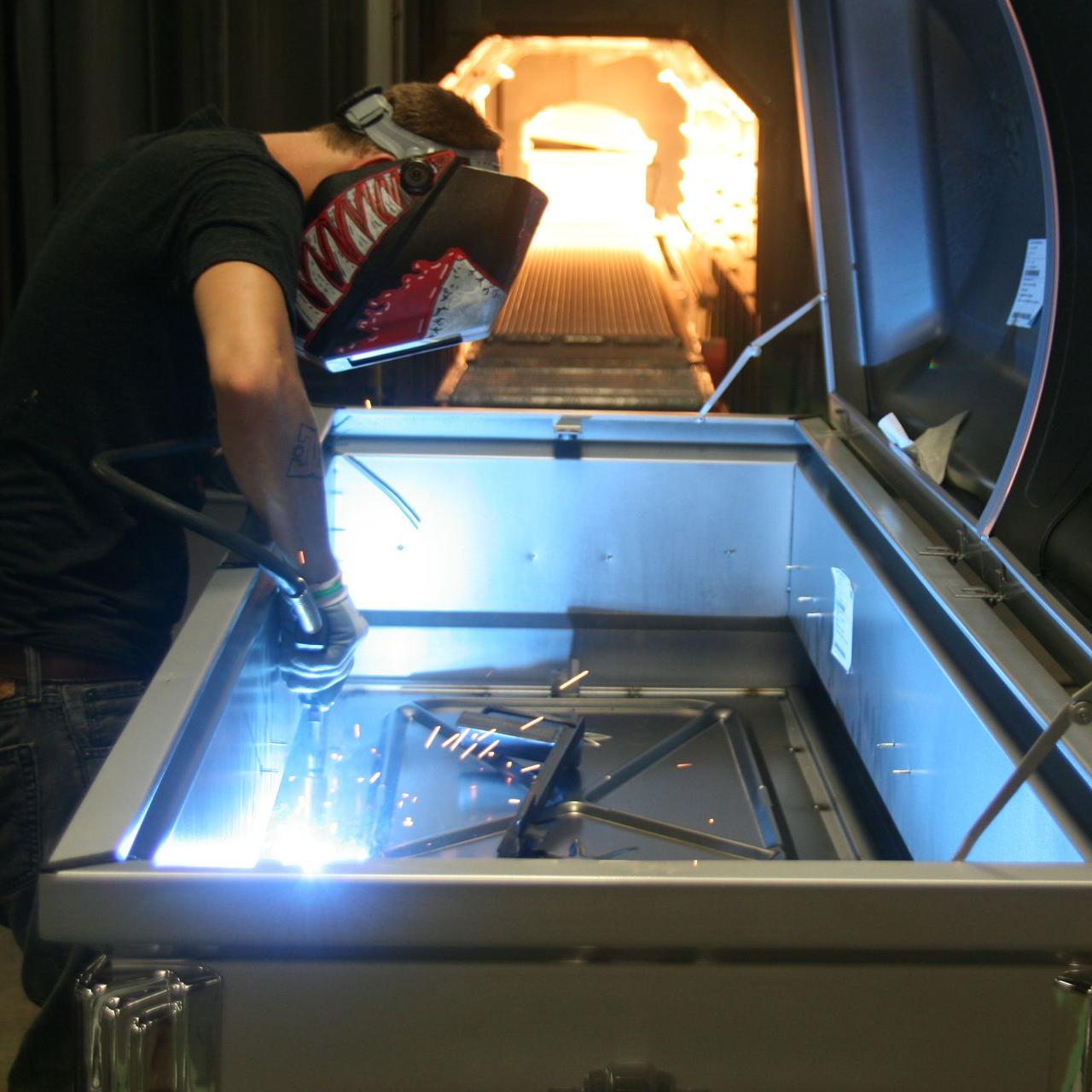

Metal Fabrication

In the metal fabrication department, the process starts with raw metal parts that have been pre-stamped from cold-rolled steel coils. Several welding stations are set up to weld the portion of the casket that forms the box. Simultaneously with the fabrication of the casket box, a group of welders will be welding together the parts of the pre-stamped lid. After all the welds are made on the box and lids, these parts pass through several people who will grind off the excess welds, making all areas of welding smooth. Once all grinding and welding is complete, the casket will then pass through an inspector who inspects the casket for any metal fabrication defects prior to moving forward into the paint department.

Paint Application

After the casket is inspected, the casket runs through a four-stage wash system that cleanses the casket of any debris that has landed on the casket during the metal fabrication process. In addition, it receives a chemical coating that etches the metal for better adhesion of paint. After the preparation wash, the casket is dried in an oven and via air knives. The majority of our caskets will then enter three separate paint booths. In the first paint booth, a painter applies the base color of the casket, and in the second booth, another painter will apply any shading or two-tone color options (if applicable). Finally, the caskets will have a clear coat application. After the clear coat, the caskets will enter an infrared oven where a “hard shell” will bake the top layer of the casket so that any debris that fell onto it in the curing process can be simply wiped off. The curing oven will cure the remaining paint at a temperature of roughly 400 degrees for 35 minutes. Thacker uses a “thermo-set” paint which is the most expensive method of painting in the casket industry but it yields the best results.

Hardware & Bed Installation

After the casket finishes the paint inspection process, a number of key components are installed on the casket. First, the bottom of the casket is welded into the casket. Afterward, a group of people will install the hardware of the casket according to both style and color specifications. Following the hardware, the bed posts are welded into the casket and the casket bed is installed. Finally, other miscellaneous components such as a gasket, tray liner, and key locking pieces are installed before the casket moves to the interior department.

Interior Installation

The final stage in the casket assembly is the installation of all the interior fabrics. At the beginning of the process, the fabric is rolled out onto a large (appx. 30 foot) table. A pattern is applied to the fabric and it is cut according to the pattern; one pattern contains all the fabric needed for one individual casket. From the cuts in the pattern, the fabric goes to various sewers who create the interior components. First, the best sheet and interior linings of the casket are installed. Next, other items such as the panel and front drop are installed. Lastly, items such as the overlay and the pillow are placed in the casket. Our interior room also features a custom embroidery area that creates the embroidered themes on Thacker’s most popular models. Thacker also offers custom embroidery for funeral homes to allow a family to further personalize a casket.