Supporting Divisions

The following are divisions and additional areas of Thacker Manufacturing that make support materials that allow Thacker to be a full supplier of funeral products.

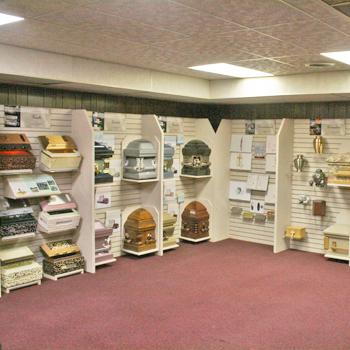

Selection Room Samples

In 2005, Thacker Caskets recognized the need for funeral homes wanting to be able to show and display caskets using casket “cuts” or “corners”. The widespread trend of using casket cuts to show and display rather than full-size caskets swept the industry in the early 2000s and is still a prevalent way of displaying caskets today. Thacker answered the call of funeral directors by creating its own selection room cut casket samples department at the manufacturing facility in Florence, Alabama. Each casket cut sample is made to order based on the selections of the funeral home. For metal caskets, the casket is built as a smaller cut and runs through the assembly line on a special tray. For wood cuts, Thacker actually takes a normal casket and makes cut samples from that casket.

Cremation & Shipping

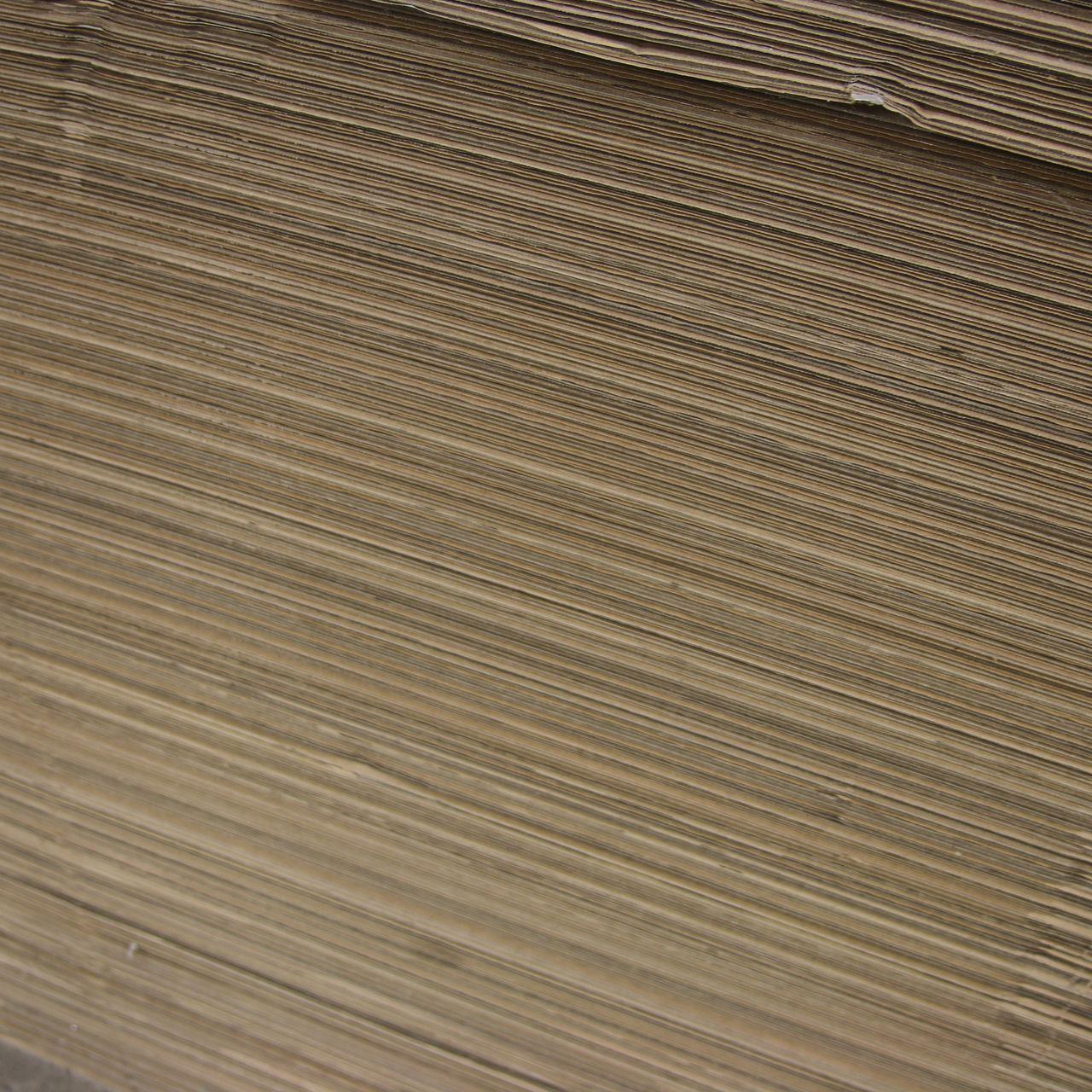

In addressing the trends of the industry, Thacker began an effort to manufacture several cremation and shipping products in-house. Many of these products were previously purchased from outside vendors, and bringing them under Thacker’s roof allowed for added product quality and pricing control. Currently in the cremation & shipping department, Thacker produces several items. Cremation items produced include economy cremation boxes, premium cremation boxes, rental casket inserts, and Thacker’s identification container called the AltaView. In addition to the cremation items, Thacker produces Air Trays which are used to ship a casketed body and Air Tray Combinations which are used to an un-casketed body.

Photo & Decal

In an effort to be nimble and flexible, Thacker has developed supporting areas of the manufacturing division. The first was the ability to print and cut our own decals. Some of Thacker’s most popular caskets are those that have themed decals on the hardware. Thacker has two machines that run all day, every day to keep up with the demand for these styles. The ability to print and cut our own decals also allows Thacker to create customizable packages such as on the Stanton casket. It allows the casket to be flexed from one theme to perhaps three or four for the family to pick from. In addition, Thacker built a photography studio right at the end of their production line. This allows any new caskets additions to Thacker’s line or caskets with updated components to be immediately photographed, keeping our photos up-to-date with the casket that the funeral home is receiving.

Shipping & Receiving

As one could imagine, Thacker has an incredibly efficient shipping and receiving department. With over two hundred individual component pieces making up the assembly of a single casket, procurement of raw materials is critically important. Not only is the procurement important, but so is the receiving and storage of those items. Thacker has a fantastic team in place to assist with all incoming inventory. In addition, Thacker’s shipping team ensures that all outbound delivery of finished goods are packaged to ensure quality and are loaded efficiently to make for a timely delivery.